Food Safety · Quality · Productivity · R&D Consulting

Food Solutions. Quality Systems. Innovation.

Helping food companies improve safety, quality, productivity, and product development through science and practical expertise.

SERVICES

Service 1: Food Safety & Quality

HACCP / ISO 22000 / FSSC 22000

BRC / IFS Systems

Supplier Assurance / Audit

Internal Audit

Service 2: Process & Productivity

Production OptimizationLine Efficiency / OEECost Reduction StrategiesProcess Troubleshooting

Service 3: NPD & EPD Development

New Product DevelopmentFormula OptimizationExisting Product Development (EPD)Cost-Down Reformulation

Service 4: Training & Coaching

Food Safety TrainingGMP / HygieneProduction SkillsQuality Culture Programs

Why Work With Me

✅ 27+ Years in Food Manufacturing

Hands-on experience in QA, Food Safety, Production and R&D across bakery, frozen dough, and industrial food processing.✅ Practical & Actionable Solutions

I focus on real-world improvements — not theoretical consultancy.✅ Measurable Results

Efficiency, cost reduction, waste reduction, better product performance, and audit readiness.✅Full-System Approach

Food Safety • Quality • Productivity • R&D — aligned to deliver real, sustainable change.

About Me

With 27 years of hands-on experience in food manufacturing, I have worked across QA, Food Safety, Production Management, and R&D — helping companies improve safety, quality, efficiency, and product performance.I specialize in frozen dough technology, bakery manufacturing, process optimization, and food safety systems (ISO 22000, FSSC 22000, BRC, IFS).

My approach is practical, science-driven, and results-oriented — focused on improving operations, reducing costs, and building high-performing teams and systems.Today, I support food businesses as an independent consultant, bringing industry knowledge, technical expertise, and a full-system approach to every project.

FEATURED WORK

A Full-System ApproachIntegrated Food Safety, Quality, Productivity, and R&D support aligned to your strategic goals.

Actionable, Technical ExpertisePractical, real-world solutions tailored to your production environment — not theoretical consulting.

Measurable ImprovementsEfficiency gains, scrap reduction, cost control, better product consistency and process repeatability.

Clear Communication & Structured Delivery

Reports, SOPs, forms, templates, and implementation steps that your team can apply immediately.

WHAT I DELIVER

Operational Clarity & StructureClear, actionable systems (SOPs, forms, checklists, workflows) that reduce confusion, improve consistency, and help your team perform at a higher level — every day.

Food Safety & Quality ExcellenceImplementation-ready frameworks for HACCP, ISO 22000, FSSC 22000, BRC, IFS, and GMP — built for real production environments, not theoretical manuals.

Product & Process OptimizationNPD, EPD, functional foods, formula optimization, cost-down reformulation, and process improvement tools that deliver measurable gains in efficiency, yield, product performance, and waste reduction.

Strategic, On-Site SupportHands-on guidance at the factory floor: audits, troubleshooting, coaching, team training, and improvement actions designed to get results fast.

TESTIMONIALS

What Clients & Colleagues Say

“Leonidas is a wonderful colleague to work with and has shown exceptional expertise in leading, coaching, and motivating others. His deep knowledge in food science and hands-on approach to consulting have earned him the respect of his teams.

A loyal, insightful professional — an asset to any business.”— LinkedIn Recommendation

“Leonidas was my first mentor in Quality Assurance. His guidance — driven by deep knowledge and a global understanding of processes — led to long-term improvements and numerous success stories.

Exceptional in interpersonal relationships and communication.”— LinkedIn Recommendation

“Leonidas is a creative and innovative R&D manager with profound knowledge of the food industry. A cross-functional, cooperative team member — and a valuable asset for any food processing company.”— LinkedIn Recommendation

“Leonidas is an expert with deep knowledge in hygiene, HACCP, and business consulting. Insightful, committed, and focused on achieving objectives — consistently leveraging his expertise and working environment.”— LinkedIn Recommendation

AI Tools for Food Manufacturing

AI-driven solutions built to improve Quality, Productivity, and R&D — tailored to real production environments.

AI-Powered Quality AssuranceAutomated QC workflows, digital checklists, real-time deviation alerts, and AI analysis of production or QA data to reduce errors and improve audit readiness.

Production Optimization with AIDemand forecasting, yield optimization models, bottleneck detection, and process “what-if” simulations that increase line efficiency and reduce waste.

AI for R&D & Functional FoodsRecipe optimization, allergen risk simulation, ingredient substitution models for cost-down reformulation, and development support for functional foods and wellness-driven products.

Custom Prompt Systems & Automation WorkflowsChatGPT-optimized prompts, SOP automation, documentation generation, and custom AI tools built specifically for QA, R&D, and production teams.

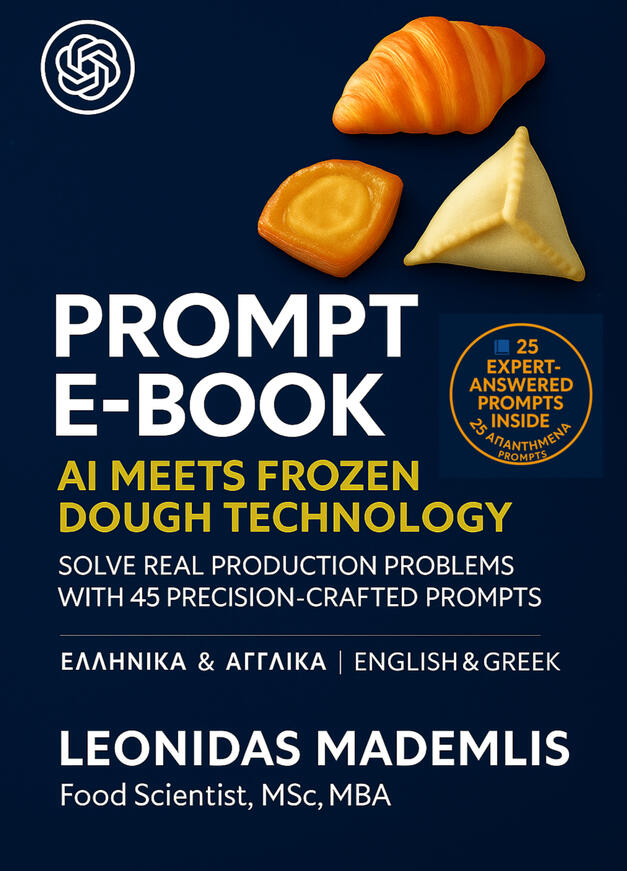

AI Meets Frozen Dough Technology

Bonus for Frozen Dough Professionals

AI Meets Frozen Dough TechnologyYour complete guide to applying AI in frozen dough & bakery manufacturing.🚀 45+ industry-ready prompts

📊 Improve quality, consistency & performance

🧪 Built for real production environments — not theory

CONTACT

Let’s discuss your project or challenges in food manufacturing.

Let’s TalkTell me briefly about your company and what you’d like to improve.I usually work with:- Food manufacturers (regardless the type of food)

- Frozen food & pastry producers

- QA, Food Safety, Production and R&D teamsYou can use the form or email me directly at

[email protected]

LDM360 — Leonidas Mademlis

Food Safety · Quality · Productivity · R&D Consulting📧 [email protected]

🌐 www.ldm360.org

📍 Thessaloniki, GreeceQuick Links

• Services

• Why Work With Me

• About

• Featured Work

• What I Deliver

• Testimonials

• AI Tools

• E-book

• Contact© 2025 LDM360. All rights reserved. Designed by Leonidas Mademlis. Built on Carrd.